What is Split Phase Induction Motor?

An alternate name

of the motor is resistance to start the motor. This motor has a single-phase

along with a stator as well as a rotor with a single cage. The stator of this

type of induction motor includes two windings like main & an auxiliary or

starting winding. The arrangement of these two windings can be done with

90°separately in space. These motors are available in different types like

resistance split-phase, capacitor split-phase, capacitor start, and permanent

capacitor.

The working

principle of a split-phase induction motor is related to a poly phase induction

motor. But the main disparity is, in single phase motor, it does not generate a

rotary magnetic field whereas the polyphase generates simply a pulsating filed.

Therefore, phase splitting can be done to generate the rotary magnetic field

for self-starting and to run the motor like a two-phase induction motor for

starting.

Split Phase Induction Motor Theory

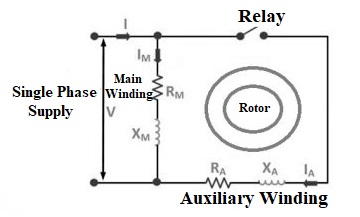

The Split phase

induction motor diagram is shown below. The following diagram can be built with

main winding resistance (Rm), main winding inductive resistance (Xm), series

resistor (Ra), inductive reactance with auxiliary winding (Xa), relay or

centrifugal switch (S). In this motor, the main winding has less resistance

& high inductive reactance whereas the auxiliary winding has less inductive

reactance and high resistance.

In the above

diagram, both the resistor & the auxiliary winding are connected in series.

The flowing current in the windings cannot be equal consequently the rotary

field is not consistent therefore, the initial torque is little. At the

beginning of the motor, the two windings are allied in parallel.

Working of Split Phase Induction Motor

Once the motor gets

the 70 to 80 % of the synchronous speed then the starting winding can be

detached automatically from the mains supply. If this motor is rated with 100

Watt or above then a centrifugal switch is utilized for disconnecting the

starting winding. Similarly, if the motor has less rating then a relay is utilized

to detach the winding by connecting in series with main winding.

Once the current

flow through the circuit, the relay gets closed. So, the starting winding is

within the circuit & when the motor gets the fixed speed, then the flowing

current within the relay will start reducing. Thus, the relay opens & the

auxiliary winding can be detached from the mains supply to make the motor run

on the main winding simply.

The current in the

main winding (IM) can be lagged behind the supply voltage ‘V’ almost by the

90-degrees of angle. The current in the auxiliary winding IA is approximately

in phase with the line voltage. Thus, there exists a time difference between

the currents of the two windings. The time phase difference ϕ is not 90

degrees, but of the order of 30 degrees. This phase difference is enough to

produce a rotating magnetic field.

Phasor Diagram

The split phase

induction motor phasor diagram is shown below. The flow of current within the

IM (main winding) can be lagged after the voltage supply approximately through

the 90 degrees angle. Here, IA is the flow of current within the auxiliary

winding can be around in phase through the line voltage. Therefore, the time

disparity among the two windings current can exist. The phase difference of

time ‘ϕ’ is not 90 degrees, but 30 degrees. So to generate the rotating

magnetic field, this phase difference is sufficient.

Advantages

The advantages of a

split phase induction motor include the following.

- The motor is economical & can be changed once it wears out before trying to reverse it.

- These are available in different frame sizes so that they can be placed effortlessly in most of the machines.

Disadvantages

The disadvantages

of a split phase induction motor include the following.

- These motors have less starting torque, so not suitable for above 1 KW.

- This motor is power output and efficiency. As compared to a 3-phase motor, these are unsuccessful while changing the energy from electrical to working.

- These motors relay simply on the different resistance & inductance of the starting winding.

- These are used where high starting torque is mandatory like an air compressor.

- These are suitable for the loads which start easily such as fans, grinding wheels etc.

Applications

The applications of

split phase induction motor include the following.

- This motor include in different loads which are used for general purpose. Generally, these loads are AC, grinders, lathe machine, drilling, Washing machines, AC fans, drill presses, centrifugal pumps, floor polishers, blowers, mixer grinder, heating blowers with belt-driven and conveyors with tiny belt-driven.

- This motor is used where the distribution of the three phases is not required.

- This moor does not give lots of starting torque, thus the load should be quite small, ad where mechanical gain can be used to assist the motor to begin.

0 Comments